Why Choose Hechang Optical?

Unveil the advantages of choosing custom-made glasses. Explore how personalized eyewear enhances comfort, offers unparalleled quality, and reflects your individual style. From innovative design to precise craftsmanship, learn how our personalized approach ensures the perfect fit, style, and comfort for your unique vision needs.

First Article Inspection: An Essential Process by Hechang Optical custom Glasses

During the design and production of any product, activities such as design changes, process modifications, process adjustments, unplanned production stoppages, and line transfers frequently occur.

So, how can we ensure that these activities do not compromise the quality of subsequent production?

At Hechang Optical, we prioritize first-article inspection during preparation verification and post-production stoppage stages to guarantee consistent product quality.

01

Definition of First Article and First Article Inspection by Hechang Optical

Process Changes

In the production process, any change in the 5M1E elements (man, machine, material, method, environment, and measurement) can occur. These changes might include personnel shifts, equipment adjustments and maintenance, material changes, fixture modifications, design alterations, or production line stoppages.

First Article

The first article refers to the initial product, or the first few products, produced at the start of each shift or after any process change. In large-scale production, the "first article" often denotes a specific number of samples that need to be checked to ensure production quality.

First Article Inspection

First article inspection involves checking the initial product or the first few products processed at the beginning of each shift or following a process change. The number of items inspected can vary according to the specific requirements of the company or client.

Typically, at least 3–5 consecutive products are inspected. Only if these pass the inspection can further production proceed. This rigorous inspection is essential whenever there are changes in equipment or manufacturing procedures and at the start of each work shift.

02

Purpose of First Article Inspection by Hechang Optical

First article inspection in the production process is crucial for preventing mass deviations, rework, and scrap. It serves as a proactive control measure, a vital technique for quality control in manufacturing, and an essential method for ensuring product quality and enhancing economic efficiency.

The primary objective of the first article inspection is to identify any factors that may impact product quality as early as possible, thereby preventing large-scale defects or waste. Formal production can only proceed after the first article inspection has been passed, ensuring that batch non-conformities are avoided.

Experience has shown that the first article inspection system is an effective way to detect problems early and prevent mass product scrapping.

Through first article inspection, systemic issues such as significant tool wear, incorrect installation, decreased measurement instrument precision, misinterpretation of drawings, or incorrect material or formula inputs can be identified. This allows for corrective actions to be taken, preventing batch non-conformance.

03

When to Conduct First Article Inspection by Hechang Optical

At the Start of Each Work Shift

This ensures that any potential issues are identified and addressed before regular production begins.

Operator Changes

Whenever there is a change in the personnel operating the equipment, a first article inspection helps verify that the new operator is maintaining the required standards.

Equipment or Tool Changes or Adjustments

Including situations such as tool replacement or re-sharpening, the first article inspection ensures that any changes do not adversely affect product quality.

Changes in Technical Specifications, Processes, or Parameters

For instance, modifications in surface roughness requirements, changing from reaming to boring of inner holes, or adjustments in CNC program feed rates or speeds necessitate a first article inspection to confirm these changes are correctly implemented.

Use of New or Substitute Materials

Whenever new materials are introduced or substitutes are used, an inspection is required to ensure they meet the necessary quality standards.

Replacement or Re-analysis of Chemical Solutions

This includes scenarios like changing or re-testing bath solutions used in processes such as phosphating or nitriding to ensure they are functioning correctly.

04

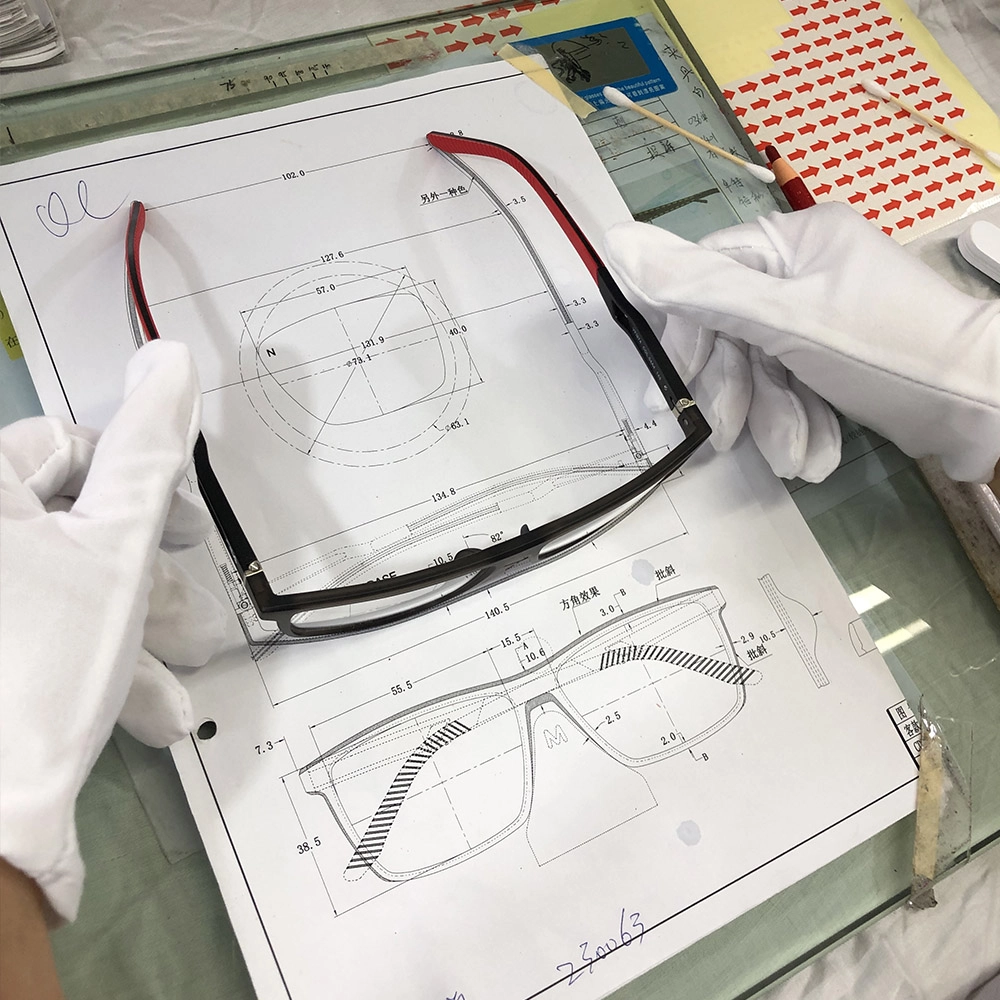

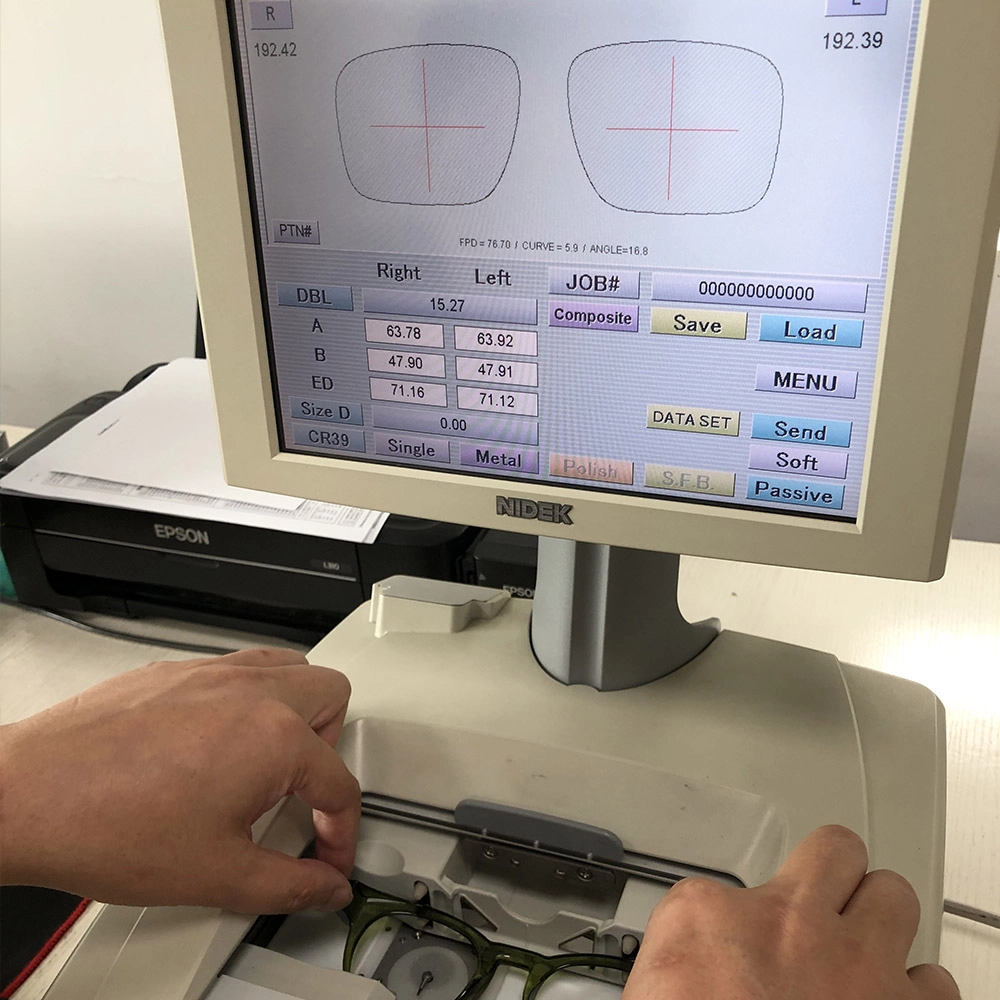

First Article Inspection Process by Hechang Optical

At Hechang Optical, we implement a three-step inspection process for first article inspection: self-inspection, peer-inspection, and specialist-inspection.

Self-inspection

The operator first conducts a self-inspection of the product to identify and correct any obvious defects.

Peer-inspection

Once the operator has completed the self-inspection, the product is then checked by the team leader or a colleague to ensure another level of scrutiny.

Specialist-inspection

Finally, the product is inspected by a dedicated quality inspector. Only after this specialist inspection confirms the product's compliance with all quality standards can subsequent production continue.

After the first article inspection, the product must be approved by the specialist inspector. Approved products are marked with a specific identifier and retained until the end of the shift or production batch.

These marked samples serve as references to ensure that the production process remains consistent and any deviations are detected. Approved first articles are marked with a "√" to indicate they have passed the inspection.

If the first article fails inspection, the cause of the failure must be identified, corrective actions taken, and the product reprocessed. The three-step inspection process is then repeated until the product passes the inspection and can be considered the first article.

05

Key Items in First Article Inspection by Hechang Optical

During the first article inspection at Hechang Optical, we focus on the following key items to ensure quality and compliance:

Drawing Number and Job Order Compliance

Verify that the drawing number matches the job order to ensure the correct specifications are being used.

Material, Blank, or Semi-finished Product Compliance

Check that the material, blank, or semi-finished product matches the job order requirements.

Surface Treatment and Installation Positioning of Materials and Blanks

Ensure that the surface treatment and installation positioning of the materials and blanks are in accordance with the specified requirements.

Formula and Ingredient Compliance

Verify that the formulas and ingredients meet the specified requirements.

Quality Characteristics of the First Article

Check that the actual quality characteristics of the first article product meet the requirements specified in the drawings or technical documents.

06

First Article Inspection Standard Procedure by HECHANG Optical

Scope and Applicability

This document outlines the requirements and procedures for first article inspection (FAI) and batch first article inspection in the company's production process.

Responsibilities

Production Department

Unauthorized Production

Inspectors and Production Line Supervisors

Premature Quality Certification

Control Requirements

01

Initial Production

The first completed semi-finished and finished product from the production department's initial continuous production must undergo FAI and confirmation.

02

Regular Production

For regular production, FAI must be conducted on a batch-by-batch basis.

03

Resumption After Downtime

When production resumes after downtime due to equipment or process issues, FAI and confirmation must be performed.

04

Material or Specification Changes

FAI and confirmation are required when product materials or specifications are changed before production can continue.

05

New Product FAI

For new products, the production unit must notify relevant inspection personnel. Inspections should follow the current drawings, lists, and process documents. Non-conforming first articles must be returned for rework immediately, with records maintained. Products that do not pass FAI cannot be accepted.

06

Sample Retention

The first article, serving as a sample for mass production, must be retained by the production department until the entire batch production is complete.

07

Sample Retention

The first article, serving as a sample for mass production, must be retained by the production department until the entire batch production is complete.

Procedure

01

Supervision During First Article Production

During the creation of the first article, the production line supervisor and inspectors must supervise and inspect the actual production on-site. They should ensure that the production follows the current effective process documents and that each production step is monitored and corrected if issues arise.

02

Completion of Production Processes

For regular production and products produced after downtime, all production processes must be completed. The producer must inspect and sign off on the first article card before it is handed over to the inspectors for FAI.

03

Conducting First Article Inspection

During FAI, the inspector and production line supervisor should inspect the product according to the current effective drawings, lists (or customer-provided samples), process documents, and product requirements. If the first article passes inspection, it should be marked accordingly (e.g., "First Article Passed") and co-signed on the first article card by the producer (or representative) and the inspector.

04

Handling Major Changes

For significant product changes requiring FAI, the relevant personnel and inspectors must sign off on the inspection. If the first article fails inspection, it must be returned for rework immediately and re-inspected.

05

New Product and Changes

The first batch production of new products and any semi-finished or finished products generated after material or specification changes must undergo FAI and confirmation.

06

Record Keeping

Timely records of the FAI should be maintained, and a first article confirmation report should be filled out.

07

Addressing Quality Issues

Any quality issues discovered during the first article production should be promptly reported and addressed. Non-conformities must be rechecked and confirmed.

Production can only proceed after a conforming first article is inspected and approved, with results recorded on the first article card and acknowledged by the inspector.

08

Normal Inspection After FAI

Inspectors can only begin normal acceptance inspections after the first article has been confirmed.

Hot sale Glasses series

According to your specific needs, we provide tailored services. From product design to packaging, we have a professional team to ensure that every aspect of each product is carefully managed.

Our Product series

Sunglasses

Sports Glasses

Ski Goggles

Optical Glasses

Feel Free to Contact Us with Any Questions You Have.

Connect with us to schedule a consultation, request samples, or arrange a site visit to see our facilities and capabilities firsthand.

Reach out to us via phone, email, or through the contact form below, and we'll get back to you promptly within 24 hours.

Rest assured that your privacy is important to us, and all information provided will be handled with the utmost confidentiality.